Boom lift solid tires have become a go-to choice for operators who work on awkward slopes, cracked pavement, or those lovely “half-dirt, half-gravel, fully unpredictable” jobsites. Anyone who has driven a boom lift on uneven ground knows one thing: if the tires aren’t stable, nothing feels stable. And when the platform is 20 meters in the air, “not stable” is the last situation anyone wants to deal with.

Before we go deeper into the technical details, you might also check a related topic – How Do Boom Lift Solid Tires Ensure Maximum Safety and Uptime on Articulating Arm and Straight Arm Vehicles? It’s a great companion piece, especially if you work with different boom models.

Why Slopes and Rough Surfaces Are Such a Problem

Working on uneven ground may look simple from afar, but a boom lift deals with some serious physics. When the machine tilts, the center of gravity shifts. If the tires compress unevenly or lose grip for even a moment, the entire platform can sway, lean, or bounce. That’s uncomfortable at ground level, and downright life-changing when you’re 40 feet up changing a signboard.

Uneven surfaces also create patchy contact points – soft soil on one side, firm asphalt on the other, loose stones scattered everywhere. Regular pneumatic tires respond by flexing, wobbling, or sinking in places you wish they wouldn’t.

This is exactly where solid tires shine.

The Engineering Behind Solid Tires That Makes Stability Possible

Solid tires might look simple, but inside that block of rubber is a highly engineered system built for tough jobsites. Let’s break down the features that actually matter when the machine is crawling up a slope or rolling over broken ground.

- No Air, No Pressure Loss, No Surprises

You know how pneumatic tires behave when the pressure drops even a little? They squish, tilt, bounce, and feel like you’re driving on a sleepy marshmallow. Solid tires don’t have that issue.

No air = no pressure fluctuation = no sudden “why is the lift leaning today?” moments.

The rigid rubber structure keeps the footprint consistent, which means the machine stays predictable whether you’re climbing a ramp or crossing uneven concrete.

- Higher Load Capacity Means Less Flex and More Control

Boom lifts carry heavy loads: the machine itself, the boom, the basket, the tools, and the people. Solid tires use multi-layer rubber compounds to manage that weight without deforming.

Less deformation = less side-to-side wobble when the boom extends.

It’s the stability equivalent of having a strong core at the gym.

- Stiff Sidewalls Reduce Leaning on Side Slopes

When a boom lift climbs a slope diagonally – yes, operators do that – pneumatic tires tend to lean outward because the sidewalls flex. Solid tires stay upright. Their rigid sidewall geometry helps the machine maintain shape even under weird angle loads.

The result? The lift feels “firm” instead of “flexible,” which is exactly what you want on uneven ground.

- Industrial Tread Patterns Provide Real Grip

Grip is everything. Solid tires for boom lifts use thick, industrial tread blocks that push into soft soil and bite into gravel. That keeps the lift from sliding, shifting, or creeping downhill when no one asked it to move.

Application Scenario 1: A Boom Lift on a Sloped Construction Site

Picture a boom lift crawling up a ramp inside a new warehouse project. The surface is half-finished concrete – smooth in some spots, rough and dusty in others. A pneumatic tire would squish and compress as weight shifts from one side to the other.

A solid tire?

It stays firm, keeps the contact patch wide, and prevents side sway as the boom rises. Operators say the difference feels like walking on solid ground instead of a trampoline.

Application Scenario 2: Working on Mixed Gravel and Soft Soil Outdoors

Now imagine an outdoor repair site where half the ground is gravel and the other half is soft, freshly dumped soil. Pneumatic tires tend to sink into the soft spots, causing a tilt even if the slope is slight.

Solid tires distribute weight more evenly. The wide footprint prevents sinking, and the rigid structure stops the machine from dipping on one side.

The boom lift stays level enough for the operator to say, “Okay, I can work with this,” instead of “I’m not getting in that basket today.”

How Solid Tires Reduce Sinking, Sliding, and Weird Wear Patterns

Wide Footprint = Less Sinking

Solid tires naturally have a broader and more stable footprint. That footprint reduces ground pressure, helping the machine float instead of drill holes in soft soil.

Stable Contact = Less Sliding

The firm structure keeps the entire tread block engaged with the surface, so traction stays consistent even when the ground beneath changes.

Predictable Wear = Predictable Handling

Because the tire doesn’t deform, it also wears more evenly. That means stability stays consistent throughout the tire’s life – not great on day one, terrible on day 200, which sometimes happens with pneumatics.

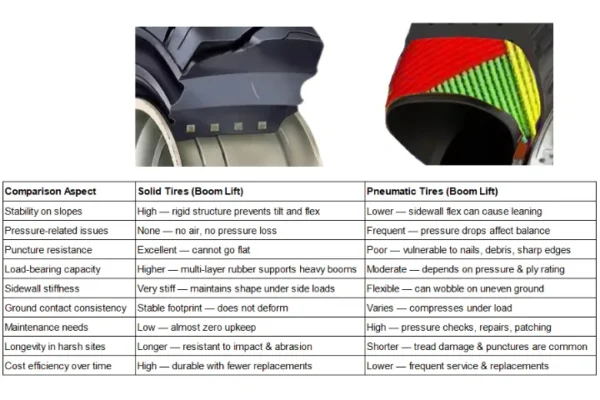

Solid Tires vs. Pneumatic Tires on Rough Terrain

- Pneumatic tires compress → solid tires stay firm

- Pneumatic tires lose pressure → solid tires don’t care

- Pneumatic sidewalls wobble → solid sidewalls stay upright

- Pneumatics risk punctures → solids never go flat

On slopes and broken terrain, every one of those differences becomes magnified. That’s why fleets working on tough sites often switch to solids despite the higher upfront cost.

What Operators Should Consider When Choosing Solid Tires

- The rubber compound hardness

- Tread pattern based on terrain

- Compatibility with your specific boom model

- Load rating for both platform height and work conditions

- Consistency across tires for predictable handling

Getting these details right makes a big difference in how the lift behaves when conditions get sketchy.

Conclusion

Boom lift solid tires prove their value the moment the ground stops being predictable. Their rigid structure, strong load capacity, stable footprint, and reliable grip make them the kind of partner you can trust on slopes, soft spots, and uneven concrete. If your jobsites are anything less than picture-perfect – and let’s be honest, most of them are – solid tires can make daily operations safer, smoother, and far more predictable.

For fleets, contractors, and rental companies, it’s worth taking a closer look at solid tire options. The long-term stability and reliability often pay off far more than expected, especially when the machines work on demanding terrain.

If you want to dive deeper into how solid tires support different boom designs, you can also check out the related article: How Do Boom Lift Solid Tires Ensure Maximum Safety and Uptime on Articulating Arm and Straight Arm Vehicles?