Excavator Tires work in places where sharp rocks, broken concrete, and uneven ground constantly hit the rubber. A tire that is not built for these harsh conditions may suffer cuts, sidewall tears, or sudden failures that stop the machine. Understanding what determines cut resistance and sidewall strength helps operators, importers, and rental fleets choose the right tires for the job and avoid costly downtime.

What Cut Resistance Really Means for Excavator Tires

Cut resistance describes a tire’s ability to withstand slicing, scraping, and puncture forces from sharp objects. Excavators face more side-scraping and twisting forces than loaders or dump trucks. When the machine turns, climbs a pile, or pulls material sideways, the tire meets high horizontal shear and edge impacts. This makes proper cut resistance essential for daily safety and stability.

Rubber Compound Engineering Behind Strong Cut Protection

The rubber compound plays a major role in how well a tire resists cuts and tearing. A higher natural rubber content gives the tire strong elasticity and tear strength, while selected synthetic rubbers improve heat stability and aging resistance. The amount and type of carbon black also influence the toughness of the rubber. Finer grades and well-balanced filler ratios help the compound absorb sudden impact forces without cracking.

In cold areas, a flexible compound prevents brittle cuts, while hot climates require heat-resistant polymers to slow down surface chipping.

Tread Architecture That Helps Defend Against Sharp Ground

Excavator Tires use blocky tread lugs that spread impact energy across a wider area. The shoulder region often includes anti-cut geometry to reduce the chance of rocks biting into the edge. Beneath the tread sits a thick under-tread layer that absorbs hidden strikes coming from angular stones. Proper stone-shedding angles also reduce embedded debris, which can otherwise dig deeper into the rubber and weaken the structure over time.

How Sidewall Strength Is Built Into an Excavator Tire

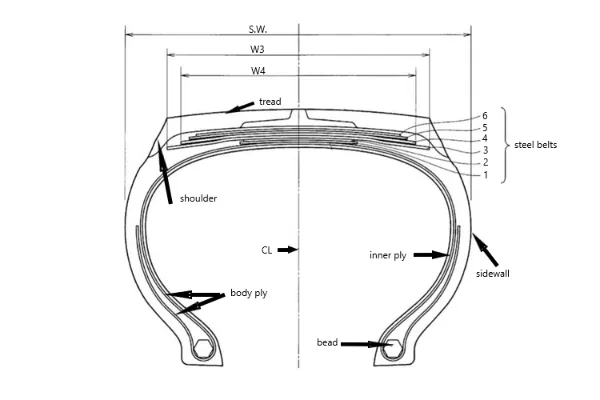

A strong sidewall protects the tire from being crushed, scraped, or sliced while the machine turns or works near obstacles. Several structural elements determine its durability:

- Sidewall thickness: Thicker gauges provide better resistance to scrapes and cuts.

- Carcass layering: High-tenacity nylon or polyester plies distribute pressure evenly.

- Bead-to-sidewall design: A reinforced transition area prevents stress concentration.

- Protective rubber shield: Added rubber layers reduce the risk of damage from rocks and debris.

These combined elements help the sidewall withstand severe lateral loads that happen during excavation, trenching, and grading.

Reinforcement Technologies That Boost Durability

Modern Excavator Tires use multiple reinforcement features, such as heavy-duty multi-ply casings, extended sidewall bumpers, and tear-energy absorbing layers. Some specialized versions are built for rock sites or demolition zones, where steel-reinforced debris often threatens the tire surface. These technologies help the tire maintain strength even under extreme working pressure.

Matching Tires to Job Site Conditions

Different job sites create different tire risks:

- Quarries and mines: Maximum cut resistance and thicker sidewalls.

- Demolition sites: Highest risk of steel and concrete edges → reinforced sidewall protection.

- Urban construction: Continuous side scraping → thicker protective rubber needed.

- Soft or muddy ground: Greater sidewall flex → strong carcass support becomes important.

Choosing based on real-world terrain helps avoid premature failure and unnecessary cost.

Maintenance Practices That Protect Cut and Sidewall Life

Good tires fail early when maintenance is neglected. Proper inflation reduces sidewall fatigue. Regular inspections help catch early cuts before they spread. Removing trapped stones and avoiding overload are simple actions that greatly extend tire life. Machines working on slopes should avoid aggressive turning that pushes too much stress onto one side of the tire.

Conclusion

The cut resistance and sidewall strength of Excavator Tires come from material engineering, tread geometry, casing structure, and practical reinforcement technologies. By understanding these factors and matching tires to the job site, buyers and operators can significantly reduce downtime and improve working efficiency.

For more information about excavator tires, please read What are the different types of excavator tires available?

FAQ

Q1: What affects the cut resistance of Excavator Tires?

A: It depends on the rubber compound, tread block design, under-tread layer, and how the tread disperses impact forces.

Q2: Why is sidewall strength important?

A: Strong sidewalls protect against scrapes, crushing, and lateral impacts during excavation and turning.

Q3: Do job-site conditions change tire requirements?

A: Yes. Quarry, demolition, and urban construction all require different levels of cut and sidewall protection.

Q4: What maintenance helps extend tire life?

A: Proper inflation, stone removal, avoiding overload, and early damage inspection