Truck tires is popular for transportation requirements in America, Africa, Asia . For truck drivers, the question of truck tires isn’t a theoretical puzzle. But for truck tires dealers, It’s about profit, reputation, and avoiding midnight phone calls from a furious client whose $200,000 rig is stuck on the side of a highway in Canada because of a blown tire.

We’ve been there. Choosing the right commercial truck tires is less about picking rubber and more about becoming a strategic partner to your clients. Get it right, and you’re a hero who saves them money. Get it wrong, and well… you know how that story goes.

So, let’s ditch the textbook and talk about the five real-world steps that actually work.

Step 1: Stop Mixing Up Your Axles – A Tire’s Job Description

Imagine wearing flip-flops to a mountain hike. That’s what it’s like putting the wrong tire on the wrong axle. It’s a comedy of errors until the bill arrives. Heavy duty truck tires have very specific job descriptions:

▪ The “Brain” (Steer Tires): These are the decision-makers up front. Their job is to stay stable, handle precisely, and wear evenly. A ribbed tread pattern is their suit and tie – professional and built to last. If these go bad, the whole truck loses its way. Not ideal.

▪ The “Muscle” (Drive Tires): These guys are all about brute force. They need deep, aggressive treads to grab the road and push 40 tons of cargo up a rainy slope in Mexico. No traction, no action. It’s that simple.

▪ The “Workhorse” (Trailer Tires): The unsung heroes. They don’t steer or drive; they just follow and carry. For them, simplicity is key. A simple tread pattern means less rolling resistance, which directly translates to fuel savings for your client. They’re the quiet, efficient type that gets the job done.

Pro Tip for Your Inventory: While specializing is key, always keep some reliable all position truck tires in stock. They’re the versatile utility players perfect for smaller fleets or emergency replacements, ensuring you never have to say “no” to a customer.

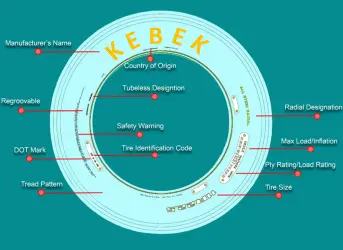

Step 2: Become a Tire Sidewall Whisperer (And Avoid Costly Mistakes)

Most of your clients will look at a tire sidewall and see hieroglyphics. Your job is to be the translator. Understanding truck tire specifications isn’t just nerdy—it’s a shield against liability.

Here’s the cheat sheet we give our partners:

▪ Size & Fit: It’s not just “11R22.5”. Make sure the rim diameter matches. Trying to fit a square peg in a round hole is a fast track to a blowout. We’ve seen it.

▪ The Safety Twins (Load Index & Speed Rating): These numbers are the law. A load index of 144/145 means the tire can handle 2,950 kg per tire. If your client is hauling near the max, skimping here is like playing Jenga with the entire load. The speed rating (e.g., ‘L’ for 120 km/h) matters too – especially for European highways.

▪ Tread & Rubber Recipe: New tread depth (e.g., 16/32″) is a good indicator of potential mileage. But the rubber compound is the secret sauce. For a distributor in Canada, you’d talk about cold-weather compounds that stay flexible. For someone in the Middle East, it’s all about heat resistance.

Step 3: Match the Tire to the Terrain (Not Just the Truck)

A one-size-fits-all approach is a sure way to miss opportunities. Your inventory should reflect the roads your clients actually travel.

▪ The All-Rounder (All Season Truck Tires): This is your bread and butter. Perfect for the general freight hauler covering mixed highways across continents. They’re the safe, reliable choice for most situations and should be the backbone of your stock.

▪ The Money-Saver (Fuel Economy Truck Tires): This is your golden ticket. With fuel prices being what they are, every fleet manager is obsessed with efficiency. These tires are engineered with special compounds and designs to reduce rolling resistance. The pitch is simple: “Yes, they might cost a bit more upfront, but let’s calculate how much diesel they’ll save over 100,000 km.” That’s a conversation that closes deals.

▪ The Style & Stability Pick (Low Profile Truck Tires): This is a niche, but a profitable one. Modern logistics companies love the sleek, stable look and improved handling of low profile truck tires. Having these in your catalog positions you as a premium, forward-thinking supplier.

Step 4: Talk TCO, Not Just Price (How to Sound Like a Financial Wizard)

When a client fixates on the price per tire, it’s your job to gently guide them to the bigger picture: Total Cost of Ownership (TCO).

Break it down for them:

▪ “That initial price is just the entry fee.”

▪ “How many miles will it last? A cheaper tire that wears out in 80,000 km is more expensive than a premium one that goes more than 150,000 km.”

▪ “Can the casing be retreaded? A quality tire can be retreaded 2-3 times, slashing the lifetime cost per kilometer.”

▪ “And let’s not forget the fuel economy truck tires we talked about. The fuel savings alone could pay for the tire before it’s even half-worn.”

Shifting the conversation to TCO makes you a consultant, not just a salesperson.

Step 5: Your Secret Weapon: A Supplier That Doesn’t Give You Headaches

Your reputation is only as good as the tires you sell and the partner who stands behind them. A unreliable supplier can sink your business with one bad batch.

What to look for:

▪ A Complete [nt manufacturing is everything. You need a partner whose quality control is so good you can forget about it.

▪ Backup When It Counts: A strong warranty and a technical support team that answers the phone are worth their weight in gold. When (not if) an issue arises, you need a partner, not a ghost.

Ready to stock tires that your clients will thank you for? <u>Check out our proven range of heavy duty truck tires and fuel-efficient tires that are built for real-world profitability.</u> For the official word on global standards, the World Tire Industry Association is a great resource.