Mining tires are not just big pieces of rubber – they are the only thing standing between a multi-ton machine and a very bad day on a brutal haul road. In real mining sites, from open-pit quarries to deep iron ore operations, tires work under extreme loads, sharp rocks, long hours, and high heat. If the wrong tire is chosen, downtime comes fast – and it comes expensive.

This article looks at why standard tires fail in mining, how heavy duty mining tires are engineered to survive harsh conditions, and how operators can select the right tire for long service life on demanding haul roads.

Why Extreme Loads Destroy Standard Tires

Mining operations push equipment far beyond what normal industrial or off-road tires are built to handle. A loaded haul truck may carry hundreds of tons, moving nonstop across uneven ground. Standard tires simply are not designed for this level of punishment.

Extreme loads cause sidewall stress, tread separation, and internal fatigue. Over time – or sometimes very quickly – this leads to blowouts, rapid wear, and unsafe operations. That is why extreme load mining tires exist in the first place.

Typical Conditions on Harsh Mining Haul Roads

Harsh haul roads are not smooth highways. They are rough, sharp, and unpredictable.

Common challenges include:

- Loose stones and sharp rock edges

- Uneven surfaces with constant vibration

- Steep grades that increase heat and load stress

- Long distances with continuous operation

On these roads, harsh haul roads act like tire testing labs – every weakness shows up fast. Even well-maintained roads still expose tires to impact damage and abrasion every single day.

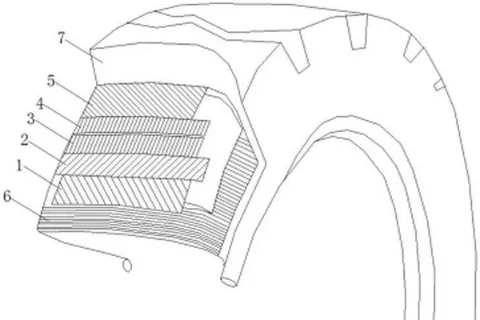

How Mining Tires Are Engineered for Heavy Duty Use

Heavy duty mining tires are engineered from the inside out to survive conditions that destroy ordinary tires.

Impact and Cut Damage from Sharp Rock

Sharp rocks are one of the biggest enemies of mining tires. A single cut can end a tire’s life early.

To fight this, mining tires use:

- Extra-thick tread blocks

- Reinforced rubber compounds with cut resistance

- Strong casing designs to protect internal layers

This helps reduce chunking, tearing, and penetration from aggressive rock surfaces commonly found in quarry and mining environments.

Load Cycles and Continuous Operation

Mining vehicles rarely rest. They move, load, haul, dump, and repeat – often 20 hours a day.

Each cycle adds stress to the tire structure. Over thousands of cycles, weak tires fatigue and fail. Extreme load mining tires are built with:

- High-strength steel belts

- Optimized ply layouts

- Reinforced bead areas

These features help tires keep their shape and strength under constant load cycling, improving safety and uptime.

Heat Buildup Under Heavy Haul Conditions

Heat is the silent tire killer. Heavy loads plus long distances create internal heat that weakens rubber and steel over time.

Quality mining tires use heat-resistant compounds that slow down heat buildup. Better heat control means:

- Longer tire life

- Lower risk of sudden failure

- More stable performance during long hauls

This is especially critical in hot climates and deep mining sites where airflow is limited.

Selecting the Right Mining Tire for Long Service Life

Choosing mining tires is not about picking the biggest size or the lowest price. It is about matching the tire to real working conditions.

Key factors to consider:

- Vehicle type (rigid dump truck, articulated truck, loader)

- Average and peak load weight

- Haul road condition and maintenance level

- Operating speed and distance

- Climate and ambient temperature

For example, rigid dump trucks working on long, rocky haul roads require tires designed specifically for stability and heat control. You can learn more about this application in our related article: Rigid Dump Truck Tires Built for Harsh Mining Roads.

This internal reference helps project buyers compare tire structures designed for rigid haul trucks operating under similar stress conditions.

Why the Right Mining Tire Is a Cost Control Tool

Mining tires are a major operating cost – but the wrong tire costs far more.

Poor tire selection leads to:

- Frequent replacements

- Higher downtime

- Increased fuel use

- Safety risks

On the other hand, well-matched quarry haulage tires and mining tires deliver:

- Longer service intervals

- More predictable performance

- Better cost per hour

In mining, reliability is not a luxury – it is the foundation of project planning and profitability.

Conclusion: Built for Weight, Rock, and Reality

Mining tires are built for reality, not theory. They carry extreme loads, survive harsh haul roads, and work nonstop in conditions that destroy ordinary tires.

By understanding how heavy duty mining tires are engineered – and by selecting the right design for your operation – mine operators and project buyers can reduce risk, control costs, and keep equipment moving.

Because in mining, when tires fail, everything stops. And nobody wants a loaded truck going nowhere.