TBR tires play a critical role in long-haul transport, especially when trucks operate under heavy loads for extended distances. They carry weight, absorb road impact, and keep rolling hour after hour, often in hot and demanding conditions. But three forces are always working against them: heat, load, and wear. If these are not managed well, even a strong-looking tire can fail earlier than expected.

This is why heavy-duty TBR tires are not just “bigger tires.” They are engineered systems designed to control heat, spread load evenly, and slow down wear – especially in long-haul transport where small problems grow fast.

Why Heat Is the Enemy of Heavy-Duty Truck Tires

Heat is invisible, but it is one of the main reasons truck tires lose life early. Many fleets only notice it after problems appear – uneven wear, weak casing, or sudden tire failure.

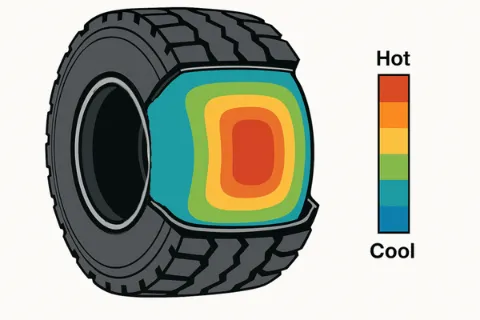

During long-haul driving, a tire bends and recovers thousands of times per hour. This movement creates internal heat. Add high speed, heavy load, and hot weather, and the temperature rises even faster. If heat cannot escape, damage builds from the inside.

Heat buildup on long hauls

On long highways, tires do not get many “rest moments.” The heat stays inside the casing, especially when loads are near the maximum limit. Over time, high temperature can weaken internal materials, reduce tread life, and make the tire harder to retread later.

Think of heat like slow cooking. Nothing looks wrong at first, but after many hours, the result is very different.

Heavy-duty TBR tires are designed to manage this problem by using special rubber compounds and internal structures that reduce heat buildup and release it more efficiently.

Load Distribution and Its Impact on Tire Wear

Many people think tire wear only depends on road conditions. In reality, how the load is carried matters just as much.

When load is not evenly shared between axles or tires, some tires work harder than others. The result is faster wear in specific areas, such as shoulders or one side of the tread.

Overloading risks in developing markets

In many emerging markets, overloading is common. Trucks often carry more weight than planned, sometimes without matching tire pressure or tire specification. This creates stress inside the tire and increases heat at the same time.

Common results include:

- One-sided wear

- Shoulder damage

- Shorter service life

This is where tire wear management becomes important. A well-designed heavy-duty TBR tire helps spread load more evenly across the footprint, reducing stress on any single area. That means more stable wear and longer use before replacement.

For fleets operating on mixed road surfaces and varying loads, this challenge is discussed in more detail in TBR Tire Solutions for Mixed Road Conditions in Emerging Markets, where load, road quality, and tire choice are closely connected.

Engineering TBR Tires for Extreme Transport Demands

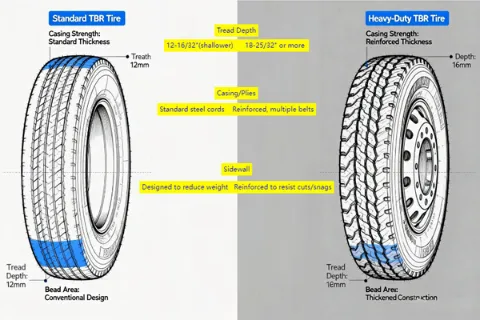

So what makes a TBR tire truly “heavy-duty”? It is not only thicker rubber or deeper tread. It is about balance.

First, the internal structure must be strong enough to handle repeated heavy loads without losing shape. Second, the rubber compound must resist heat while staying flexible. Third, the tread design must keep the tire stable and reduce unnecessary movement.

When these elements work together, the tire runs cooler, wears more evenly, and keeps its strength over long distances.

This engineering approach is why heavy-duty TBR tires often deliver better long-haul durability, even if the outside looks similar to standard tires.

Selecting TBR Tires for High-Load Applications

Choosing the right TBR tire is not about buying the strongest tire on paper. It is about matching the tire to real working conditions.

For high-load, long-haul transport, buyers should look at:

- Actual load per axle, not just vehicle rating

- Typical driving distance per trip

- Road temperature and surface quality

A tire that manages heat well and wears evenly often delivers lower cost per kilometer, even if the purchase price is higher. In other words, the cheapest tire is not always the most economical one.

Heavy-duty TBR tires are designed to keep working when conditions are tough. When heat, load, and wear are under control, fleets gain something very valuable: predictability. And in long-haul transport, predictable performance is worth a lot more than surprise savings.