Puncture proof solid tires are not just a technical feature – they are a risk management decision for operations that cannot afford unexpected downtime, safety incidents, or constant tire maintenance.

In many industrial environments, punctures are treated as “part of the job.” A nail on the floor, sharp scrap metal, broken pallets, or uneven ground – these hazards are everywhere. But what is often ignored is how much uncertainty puncture risks quietly add to daily operations. Solid tires remove that uncertainty completely.

Why Puncture Risks Are a Hidden Cost in Industrial Operations

Common puncture sources in warehouses and construction sites

Punctures rarely come from dramatic accidents. Most of the time, they come from small, routine hazards:

- Loose nails and metal fragments

- Sharp pallet edges

- Scrap materials and broken concrete

- Debris left behind after maintenance work

In warehouses and logistics centers, these hazards appear gradually and unpredictably. On construction sites, they are unavoidable by nature.

The real cost of tire failures goes beyond repair

A punctured tire is not just a tire problem. It creates:

- Unplanned equipment downtime

- Sudden task interruption

- Extra labor for tire replacement

- Safety risks during emergency stops

This is why many fleet managers now see punctures not as a maintenance issue, but as an operational risk.

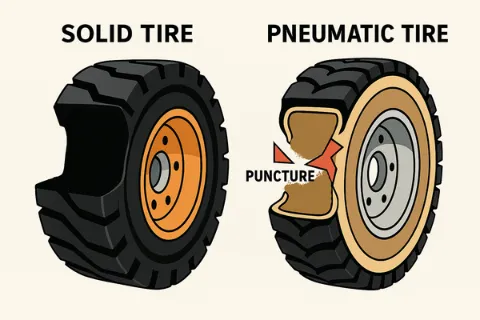

Why Pneumatic Tires Struggle in Demanding Work Environments

Air pressure is the weak point

Pneumatic tires rely entirely on air pressure. That makes them flexible and comfortable – but also vulnerable. Even a small sharp object can cause slow air loss or sudden failure.

In environments with:

- Heavy loads

- Low-speed, high-torque movement

- Continuous start-stop cycles

air-filled tires simply operate outside their comfort zone.

Repairs treat symptoms, not the problem

Patching, reinflating, or replacing pneumatic tires helps only temporarily. The environment does not change, so punctures return. Over time, this creates a cycle of repeated intervention rather than a long-term solution.

This is where maintenance-free tire strategies become attractive.

How Solid Tires Are Truly Puncture Proof

No air, no puncture

Solid tires eliminate air completely. With a one-piece or multi-layer solid rubber structure, there is nothing to leak, burst, or lose pressure.

This makes solid tires:

- Immune to nails, glass, and metal debris

- Unaffected by slow leaks

- Fully operational even after surface cuts

Consistent performance from day one to end of life

Because there is no air pressure involved, load capacity remains stable over time. Operators do not experience the gradual performance drop that often comes with underinflated pneumatic tires.

This consistency is a major reason why solid tires are widely used in high-risk environments where predictability matters more than ride comfort.

Where Solid Tires Deliver the Most Value

Warehouse and logistics operations

In busy warehouses, even short interruptions cause delays across the entire workflow. Many operators already use solid tires in forklifts for this reason.

For a deeper look at this application, see

How Solid Forklift Tires Improve Stability When Working in Tight Warehouses

Construction and infrastructure projects

Construction sites combine sharp debris, uneven ground, and heavy loads. Solid tires remove puncture risk from the equation and allow machines to keep moving without constant checks.

Operations where downtime is not an option

Some environments simply cannot stop unexpectedly. This is why solid tires are often chosen in operations where uptime is the priority rather than speed.

You may also find value in

Solid Tires for Operations Where Downtime Is Not an Option

Solid Tires vs Pneumatic Tires: A Practical Comparison

Puncture resistance and safety

- Solid tires: 100% puncture proof

- Pneumatic tires: Always vulnerable to sharp objects

Maintenance and lifetime cost

Solid tires usually cost more upfront, but they remove:

- Tire pressure checks

- Emergency repairs

- Unexpected replacement schedules

Over the full service life, total operating cost is often lower.

Comfort and speed trade-offs

Solid tires are stiffer and better suited for controlled industrial speeds. They are not designed for high-speed transport – but that is rarely required in demanding work environments.

How to Choose the Right Solid Tire for Your Operation

Match load capacity to real working conditions

Always select solid tires based on actual operating load, not theoretical equipment limits.

Consider floor and ground conditions

Indoor smooth floors and rough outdoor surfaces require different rubber compounds and tread designs.

Work with a manufacturer, not just a reseller

Consistent quality, proper bonding, and application-specific design matter. A manufacturer with solid tire experience can help avoid mismatched solutions.

Conclusion: Turning Tire Choice into Risk Control

Solid tires do not just replace pneumatic tires – they eliminate a category of risk. For operations where punctures create uncertainty, delays, and safety concerns, solid tires offer a clear, maintenance-free path forward.

By choosing puncture-proof solid tires, companies gain predictability, stability, and confidence in demanding work environments.