Mining tire costs are carefully tracked in most mining operations. Fuel cost, labor cost, and maintenance cost are all recorded in detail, often down to the last dollar. Tire cost is also monitored closely and regularly reviewed.

And yet, many mines still see their cost per ton moved slowly creeping up over time.

The reason is simple.

Most cost reports focus on what tires cost to buy, not on what mining tires actually cost to run in daily operations.

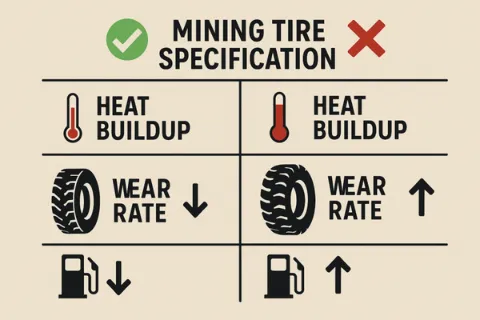

In reality, the biggest losses usually come from mining tire specification mistakes. These mistakes are quiet, slow, and easy to ignore, but they affect fuel use, tire life, downtime, and productivity every single day.

This article explains how wrong mining tire specifications increase cost per ton moved, and how a more data-driven approach can lower total hauling cost without changing trucks or haul routes.

Why Many Mines Track Tire Cost – But Miss the Real Loss

Tire Purchase Price vs Hidden Operating Cost

A tire with a lower price looks good on a purchase order. But once it is mounted on a haul truck, the real cost starts.

If a tire runs hotter than expected, wears faster, or fails early, the mine pays again – in fuel, downtime, and lost production. These losses rarely appear in tire purchase reports, but they show up clearly when you calculate cost per ton moved.

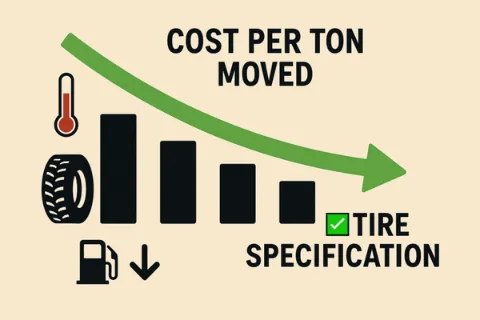

Why Cost per Ton Moved Reveals Specification Problems

Cost per ton moved connects tire performance directly to production output.

Two mines may use the same truck model and similar tires, but different specifications can lead to very different results.

When cost per ton increases while equipment stays the same, tire specification is often the missing piece.

The Most Common Mining Tire Specification Mistakes

Overspecifying Load Capacity “Just to Be Safe”

This is one of the most common mistakes.

Choosing a tire with a much higher load rating than required may feel safer. In reality, it often causes excess heat buildup, especially on longer haul cycles. More heat means faster aging and shorter tire life – and higher cost per ton.

Choosing Cut Resistance When Heat Is the Real Enemy

Sharp rocks are easy to see. Heat is not.

Many operations select very cut-resistant compounds even when heat, not cuts, is the main problem. The result is a tire that survives cuts but fails early due to internal damage. Wrong protection is still wrong protection.

Using One Tire Specification Across Different Haul Profiles

Not all haul roads are the same.

Short cycles, long cycles, flat roads, slopes, and road maintenance levels all affect how a tire behaves. Using one specification for every route may simplify purchasing, but it usually increases operating cost.

How Specification Mismatch Increases Cost per Ton Step by Step

Higher Rolling Resistance Raises Fuel Consumption

A tire that is too stiff or poorly matched to the road surface increases rolling resistance. The truck needs more energy to move the same load, and fuel consumption rises quietly, shift after shift.

Faster Wear Shortens Tire Life

Incorrect specification often leads to uneven or rapid wear. Tires reach their removal point earlier than planned, increasing replacement frequency and raising haul truck tire cost.

Unexpected Failures Increase Downtime Costs

Early failures do not just affect the tire budget. They stop trucks, delay cycles, and create unplanned maintenance work. Every stopped truck pushes cost per ton higher.

Mining Tire Specification Should Start with Data, Not Product

The Operational Data That Actually Matters

Good tire specification starts with a few key questions:

- What is the real average payload, not the theoretical one?

- What speed do trucks actually run?

- How long is the haul cycle?

- How well are haul roads maintained?

This data matters more than brand names or catalog descriptions.

Why Tire Size Alone Is Never Enough

Two tires with the same size can perform very differently. Structure, internal design, and material selection decide how the tire behaves under real conditions. Size tells you where the tire fits; specification tells you how it works.

For operations working under heavy load conditions, it helps to understand how tire structure supports load and heat management.

Related reading: Mining Tires Designed for Extreme Loads on the World’s Toughest Haul Roads

A Cost-Focused Way to Evaluate Mining Tire Options

Comparing Tires by Cost per Ton, Not Cost per Unit

Instead of asking, “Which tire is cheaper?” a better question is:

“Which tire moves more material for the same total cost?”

Cost per ton highlights the full picture – fuel, wear, downtime, and service life.

When a Higher-Spec Tire Is Actually Cheaper

In high-utilization operations with long haul distances, a higher-spec tire often delivers lower cost per ton because it lasts longer and runs more efficiently.

When It Is Not – and Why That Matters

In slower, shorter cycles, overspecification can waste money. Matching specification to real conditions avoids paying for performance you never use.

For rigid dump truck applications on demanding haul roads, proper matching becomes even more critical.

See also: Rigid Dump Truck Tires Built for Harsh Mining Roads

How Mines Can Reduce Cost per Ton Without Changing Equipment

Adjusting Tire Specification Instead of Replacing Trucks

Changing trucks is expensive. Adjusting tire specification is not. Small changes in structure or compound can deliver measurable savings without new equipment.

Fine-Tuning Specs for Different Pits or Mine Phases

As mines expand or move to new areas, haul conditions change. Tire specifications should change with them.

Working with Suppliers Who Understand Operating Data

Suppliers who focus on operating data – not just product catalogs – are better partners for cost control. A good specification is the result of understanding how the mine really works.

Specification Mistakes and Their Cost Impact

| Specification Mistake | What Happens in Operation | Cost Impact |

| Overspecified load rating | Excess heat buildup | Shorter tire life |

| Wrong compound choice | Heat or early damage | Higher downtime |

| One spec for all routes | Low efficiency | Higher fuel cost |

| Ignoring real TKPH | Chronic overheating | Higher scrap rate |

| Over-aggressive tread | High rolling resistance | Higher cost per ton |

Most of these losses are invisible in purchase reports, but very clear in cost-per-ton analysis.

Conclusion

Mining tire specification is not about choosing the strongest tire. It is about choosing the right tire.

When specifications match real operating conditions, tires run cooler, last longer, and help trucks move more material with less fuel and fewer interruptions. That is how mines lower cost per ton moved – not by buying cheaper tires, but by making smarter specification decisions.