When you look at excavator tires, it’s easy to think they’re just big, round pieces of rubber. But in quarry pits and construction sites, these tires deal with sharp rocks, unstable soil, and operators who sometimes believe their machine is a superhero. Whether you’re sourcing quarry tires, construction site tires, or heavy duty OTR tires, choosing the right setup can reduce downtime, improve safety, and save a lot of money (and headaches).

Why the Jobsite Matters More Than You Think

Quarry and construction environments may both be “messy,” but they stress tires in very different ways.

Quarry sites are full of sharp rocks, high-impact surfaces, and constant stop-and-go movements. Tires face an endless stream of cutting, chipping, and heat buildup. It’s basically a rock-chewing fitness test for rubber.

Construction sites, on the other hand, have mixed terrain – mud, soft soil, broken concrete, and uneven ground. Traction and stability matter more, especially when the operator is maneuvering in tight areas and pretending the excavator is a ballet dancer.

Before diving into the technical details, readers who want to review the different tire categories can check the internal reference: What are the different types of excavator tires available?

Tread Designs: L2, L3, L4, and L5 (The Tire’s “Armor Level”)

Tread patterns are where most of the magic (and engineering) happens.

- L2 / L3: Ideal for construction sites. Better traction, good mud-cleaning performance, and balanced durability.

- L4: A step up in toughness for rougher surfaces.

- L5: Maximum cut resistance and the thickest tread- perfect for aggressive quarry surfaces where sharp rocks eat weaker tires alive.

Deep tread blocks offer better impact protection but increase heat. Shallow blocks reduce heat but compromise cut resistance. The right choice depends entirely on where the machine spends most of its time.

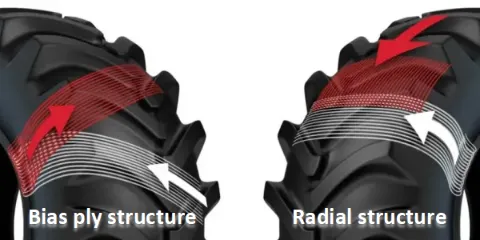

Tire Structure: Radial vs. Bias (The Eternal Debate)

The same operator who insists he “knows everything” about excavators usually has strong opinions here – but let’s break it down simply:

Bias (Diagonal) Tires

- Stiffer sidewalls

- Better resistance to impact and rock strikes

- Preferred in quarries or very harsh terrains

Radial Tires

- Cooler running temperatures

- Better tread life

- More flexible casing for improved comfort and traction

Bias tires behave like a heavyweight boxer absorbing punches. Radial tires are more like long-distance runners – efficient and steady. Your jobsite decides which athlete you need.

Rubber Compounds: The Secret Ingredient

Yes, rubber is rubber – but industrial tire compounds can vary like coffee recipes.

- More carbon black → higher wear resistance

- More synthetic rubber → improved cut resistance

- Optimized curing systems → stronger sidewalls

For quarries, look for high-cut-resistance compounds. For construction, prioritize traction and heat control. The wrong compound will turn a tire into a very expensive chew toy for rocks.

Ply Rating & Steel Reinforcement

Higher Ply Rating (PR) means stronger, tougher, and heavier – but also rougher to operate. In quarries, 16–24 PR is common; in general construction, lower PR often provides enough strength while improving ride comfort.

Steel belt design affects:

- Deformation resistance

- Load capacity

- Sidewall protection

Think of it like choosing armor: light armor for flexible movement, heavy armor for brutal battlefields.

Matching Tire Specs to Real-World Work

Quarry Work (High Shock, High Cuts, High Drama)

- Tread: L4–L5

- PR: 16–24

- Structure: Usually Bias

- Compound: High cut-resistance

- Sidewall: Reinforced

These setups resist rock strikes and constant impacts, keeping downtime low.

Construction Work (Mixed Terrain, Higher Mobility)

- Tread: L2–L3

- Structure: Radial or Bias depending on load

- Compound: Balanced wear + traction

- Features: Good self-cleaning tread design

These tires help prevent slipping, sinking, and unnecessary operator “hero moments.”

Maintenance: The Part Nobody Loves but Everybody Needs

Even the best excavator tire can fail if ignored.

- Check pressure regularly- underinflation increases cut danger; overinflation kills traction.

- Rotate positions to balance wear.

- Inspect sidewalls for cuts, bulges, and heat cracking.

- Control speed and load according to manufacturer guidelines.

Think of maintenance as a gym routine for tires – skip it, and things go downhill fast.

Conclusion

Choosing the right excavator tires for quarry and construction work isn’t just about size or price. It’s about pairing the correct tread design, structure, compound, and PR with the ground conditions your machine faces every day. When the setup is right, your fleet gets better safety, longer tire life, and a lot fewer unpleasant surprises.

For readers who want to understand tire categories in more detail, don’t miss the internal reference: What are the different types of excavator tires available?