Farm tires play a major role in how modern agricultural machines deliver traction, protect the soil, and keep fuel consumption under control. Among all tire structures, bias farm tires and radial farm tires are the two most common designs. Each works differently in the field, and choosing the wrong one can affect performance, productivity, and long-term costs. This guide compares both types in real farming situations to help growers, dealers, and importers make better choices.

What Makes Bias and Radial Farm Tires Different?

Internal Construction

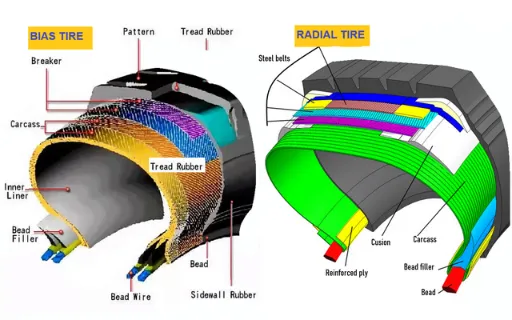

Bias tires use multiple diagonal plies that overlap from bead to bead. This creates a strong, rigid casing.

Radial tires, however, use belts running at 90 degrees to the direction of travel, with additional steel or fabric belts under the tread. This design separates the functions of the tread and sidewall, allowing each part to flex differently.

How Construction Shapes Performance

- Radials have a wider, more consistent footprint.

- Bias tires distribute load through overlapping plies, giving the sidewalls more stiffness.

- Radials manage heat better, especially during long-distance or high-speed transport.

Performance in Real Farm Work

Traction

Radial farm tires grip the soil better due to their larger footprint and flexible sidewalls.

Example scenario: When pulling deep rippers, heavy cultivators, or large planters, radials help maintain traction without excessive wheel slip.

Bias tires work well on older tractors or in short-distance tillage where top traction is not the priority.

Ride Comfort

A softer sidewall allows radial tires to absorb vibration more effectively.

Field example: Operators driving over rough headlands or uneven fields during fertilizer spreading feel fewer bumps with radials. Bias tires feel firmer, which can be useful when carrying heavy loads at low speed.

Fuel Efficiency

Less rolling resistance makes radial tires more fuel-efficient. Over a full planting season, this difference becomes significant.

Bias tires consume more fuel, especially when operating long hours in transport or fieldwork.

Soil Compaction

Radial tires spread weight over a larger area.

Typical use case: On corn, soybean, or wheat farms where soil structure needs protection, radial tires lower compaction levels and improve yield potential.

Bias tires concentrate pressure more, which can lead to deeper ruts in wet ground.

Durability and Damage Resistance

Bias tires are known for toughness.

Worksite example: Orchards, forestry fields, or rocky land with tree roots and stumps often favor bias because the stiffer sidewall resists cuts.

Radials last longer under normal field use but rely more on correct inflation and careful handling.

Cost and Lifetime Value

Bias tires are cheaper to buy, making them attractive for smaller farms or older machines with low yearly working hours.

Radial tires cost more upfront but deliver longer tread life, reduced fuel use, better traction, and lower soil damage. Their lifetime value usually outweighs the price difference for full-time farming operations.

Which Farm Tire Type Fits Your Machine?

Choose Bias Farm Tires When:

- You run loaders, scraper tractors, or implements in rocky or wooded land

- Speeds are low and distances short

- Budget is limited

- Equipment is older and mainly used for periodic tasks

Choose Radial Farm Tires When:

- You operate modern high-horsepower tractors

- You focus on row-crop farming or precision agriculture

- Long working hours, long transport routes, or wet soil conditions are common

- Soil protection and fuel efficiency matter

Avoid These Common Mistakes

- Choosing only by price instead of total lifetime cost

- Ignoring air pressure requirements

- Using the wrong tire structure for field vs. transport

- Mixing bias and radial tires on the same axle

Conclusion

Bias and radial farm tires each have places where they perform best. Bias tires offer strength and affordability, while radial tires deliver superior traction, comfort, and soil protection for today’s high-performance agricultural machines. By matching tire type to the field conditions and the machine’s workload, farmers and fleets can improve productivity and reduce long-term costs.

Recommended Reading: How to Read Agricultural Tire Sizes and Specifications